The Perfect Clutching Myth

by Donavon W. Facey

One of the most enjoyable parts of the powersports industry is the wide variety of aftermarket parts available for the machines we ride. Unfortunately, one of the most frustrating aspects of the our industry is the fact that a lot of what’s sold simply doesn’t do what is promised. Our testing program often puts us in a killjoy role because close scrutiny of most mod products simply doesn’t bear out the marketing claims. In the last few years, if a product made half the horsepower promised, we were generally impressed. Sometimes, a promised 3hp was actually a 2hp loss or worse. Beyond products that are supposed to increase horsepower, the ATV and Snowmobile markets are also filled with clutch products that supposedly “put more power to the ground.” Oftentimes, these products are marketed on the basis of providing a magical, mystical “perfect” clutch setup that can only be achieved by buying their parts. Unfortunately, the basic physics involved with constantly variable transmissions (CVTs), especially when riding at high altitude, or in changing terrain or snow conditions, makes the notion of a “perfect” setup entirely unrealistic.

Over the years, we’ve been involved in testing and riding lots of modified sleds and ATVs. In fact, when we named the store, we picked “Xtreme” because we wanted the name of the dealership to reflect our commitment to really making our machines run well. In stock form, that means having the clutching, jetting, gearing, etc. all optimized for a variety of conditions. The reality, though, is that no matter how much tuning you do with a stock engine, there’s only so much horsepower there to work with. Once you have the air/fuel mixture set for peak power, tuning on the drivetrain really is a question of using that power efficiently. In very simple terms, the function of the clutches are to hold the engine at peak horsepower RPM so that the engine can generate peak power.

We had about a $15k experiment with a Dynojet track dyno years ago before we really understood that if you don’t make more power at the crankshaft, no amount of tuning is going to make the sled appreciably faster in MULTIPLE conditions. While it is possible to gain performance if the clutching is markedly off, fine tuning the setup really can’t make the sled better in every condition. It’s possible to build a setup that drag races really well or one that’s really snappy in the trees, but as they use to say in my economics classes, “there’s no such thing as a free lunch.” If you make the sled better in one spot, there’s always a trade-off. For example, at Bandimere and a quarter mile drag race, we run absolutely the heaviest clutching the engine can handle without underreving. The faster the sled upshifts, the faster it goes down the track. We don’t normally need the clutches to backshift nor does throttle response matter since we only mash the throttle once. The track dyno essentially told us the same thing: the faster you upshift the clutch, the more power gets to the track sooner. That’s great until you actually go ride the sled and find out that it simply doesn’t backshift and has no throttle response because the clutching is so heavy. In real life, it’s fun to go fast in a straight line across the meadow. However, when you have to lift in the trees and then get back in the throttle and the engine takes an eternity to return to peak RPM leaving you with the headlight pointed at the sky and the track buried in a big hole, that’s not so much fun.

That trade-off is really the reality of clutch tuning that the purveyors of magical, mystical snake oil clutch kits don’t want the average consumer to understand. That’s certainly not to say that having a good clutch setup isn’t important, but there is simply no clutch kit or setup that works “perfectly” all the time. Why? To start with, we have to agree that if you want the snowmobile or ATV to perform at its’ best, it has to turn the RPM at which the engine develops peak horsepower. If you want to understand why clutching for peak torque or any other RPM doesn’t work, there’s a great article on www.dynotechresearch.com where Jim Czekala discusses that. In short, horsepower is a measurement of work done. In our case, the work we want done is propelling the machine and peak power RPM is, by definition, the RPM that most work gets done. Generally when we do all of our clutching calibration, we are looking for a setup that keeps the engine at or near peak power RPM most of the time. That’s sound a little like a hedge, doesn’t it? The plain truth is that given a strictly mechanical CVT, any time horsepower changes, the RPM that the clutches operate will change as well. You simply cannot vary the horsepower and not vary the RPM.

For example, I always like to think about riding in Grand Lake one day and then heading over to Vail the next day. If you do that, the engine will make a considerably lower amount of power on Vail than it did at Grand Lake. Therefore, if we don’t change our clutch components, the engine will turn less RPM. With less power at the crankshaft and the same load being exerted on the engines by the clutches, the engine simply won’t have the power to spin the clutches as fast. Less power also means the machine will obviously accelerate more slowly. If your clutching was truly optimized at Grand Lake, you’ll actually have a double whammy at Vail because you’ve lost horsepower at higher altitude and then the engine won’t be turning peak power RPM, thereby inducing additional power loss.

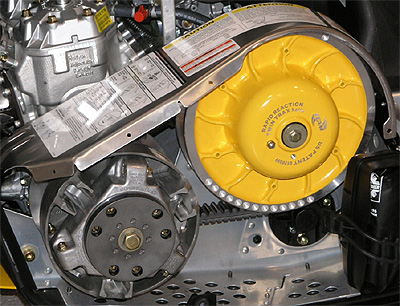

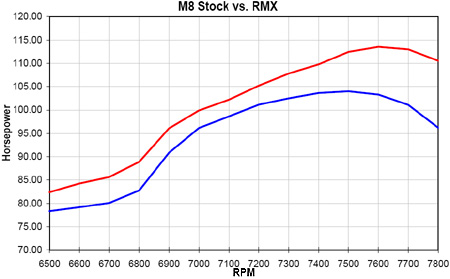

Looking at the M8 RMX dyno curve below, we can see how this double loss of horsepower would actually play out. To put things in context, it’s beneficial to note that the M8 engine, especially with the RMX kit, has a fairly broad powerband, obviously tuned by the Suzuki engineers to have good bottom end and mid-range power. The phenomena we’re discussing here could actually be much worse with a “peaky” engine that had been tuned for maximum horsepower at peak RPM. Again, there are no free lunches so if you have an engine that makes more peak power, it’s at the expense of low and mid-range power. A Polaris 700 with no compression and twin pipes would be a good example of that type of powerband. For reference, our dyno sits at 6,500’ and the data is corrected to 23.80” Hg, 60° and dry air. If you do the density altitude calculations, you’ll find the atmospheric conditions at the dyno are roughly equivalent to 8,000-8,500’ of altitude at our typical 0-30° riding temperatures. For the sake of simplicity, let’s assume that our M8 RMX is ripping across Grand Lake turning right at 7600rpm, and, therefore, is making the dynoed horsepower of 113.54. If we then load the sled up and head to Vail, we would probably see the atmospheric pressure drop roughly about 2” Hg as we gained that 2,500’ in altitude. The calculator tells us that a 2” Hg loss in atmospheric pressure would then cost the sled about 9.2% of its power, and we’d end up with about 103hp. All our testing over the years has taught us that snowmobiles lose about 100rpm per 1,000’ of altitude gained, in stock or modified form. Getting back to our M8 at Vail, we’ve already lost about 13.5hp to the thinning air. Because the clutching is now not optimized, the sled will be turning 7300-7400 rpm. Looking at the dyno curve, we see that at 7400 rpm, the engine only made 109.79 hp at our baseline altitude, and only 107.81 at 7300 rpm. Let’s split the difference and figure we had about 108.8 hp at 7350. If we then correct that number to the 11,000’ atmosphere, we would then only have 98.8 hp. Wow, one little trip from Grand Lake to Vail and we’ve gone from riding a 113.5hp sled to riding one only making 98.8 hp. That’s essentially a 15 hp loss, or a whopping 13% of the measly amount of power we had to start with. No wonder those 125hp 600s feel so good at sea-level compared to what we’re used to!

Now that we understand the effects of altitude on crankshaft horsepower and how that effects our clutching, what’s the solution? The reality is, given the physics that we’re dealing with, you really have only two options. You can continually adjust the clutching as altitude changes to keep the engine right on the sweet spot or you can set your clutching up to work most of the time. When we develop our setups for how the ATVs or sleds leave the shop, our intent is to find the best all around setup. For snowmobiles, at 9,000’, the sled has to overrev some, they’re very close to peak horsepower RPM at 10,500’, and they underrev 100-200 rpm as you climb up to 12,000’. If we have customers who tell us they always ride someplace high like Cottonwood or Vail where it’s tough to hold RPM, we lighten the clutching up for them. If they go to Grand Lake and ride, will the sled overrev and be slower than it should be? It has to. Ski-Doo has addressed the problem somewhat with the TRA series clutches and its’ clickers which allow the rider to easily change operating RPM, without changing clutch parts. The drawback to the Ski-Doo clutches is that they generally are not as stable as the other style clutches used by Polaris, Cat, and Yamaha. It’s good they are adjustable, because it’s almost inevitable that they’ll need to be adjusted.

The fundamental conclusion after this discussion is that if there was a “perfect” clutch setup, it would only be perfect for a certain set of conditions. Changing the terrain, atmospheric or snow conditions, or even rider weight would certainly make the setup somewhat imperfect. For those riders who really want to maximize their sleds’ performance, the only answer is to watch the tach and adjust if you find the engine is not turning peak horsepower RPM most of the time. Thankfully, the manufacturers are finally giving us some accurate, digital tachs that we can watch and read. If, however, your sled is turning nearly peak horsepower RPM, enjoy the ride knowing that you’re sled is running well and no magic clutching would make it appreciably better.